Concrete. When you think of it, you think of solid, durable, everlasting. With the local and family-owned Concrete Technology Corporation (CTC), that’s true not only of their product, but of their unique business as well. From the 38th Street Interchange to the Museum of Glass, their projects have helped create the landmarks that make our city and far beyond.

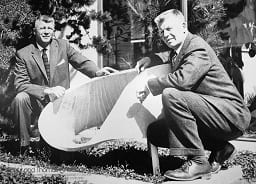

Founded 67 years ago by a pair of brothers, Thomas and Arthur Anderson, Concrete Technology Corporation has stood the test of time for their innovation and commitment to how they treat their workers. Right here at the Port of Tacoma, the Andersons created the first manufacturing plant in the United States to make pre-stressed concrete, which is stronger, more predictable, and handles impact better than its traditional counterpart, reinforced concrete. From developing their first bridge girders (support beams) in the 1950s to completing Cheney Stadium and the Seattle Monorail girder in the 1960s, they’ve been paving the way ever since.

Walking through their present-day plant is an impressive experience. On any given day, you’ll find teams of workers in protective gear trying rebar and brooming concrete on pieces over a hundred feet long. The company takes on projects around the Northwest and can also transport products with barges from their onsite dock. They haul gravel loads by water via tugboat from DuPont, and still mix their own concrete onsite. Around the clock, in all weather, Concrete Technology is producing.

The sheer scope of their projects is something to make you stop in awe. Did you know Concrete Tech built the A Street Garage and the State Route 16 Nalley Valley Interchange? They are responsible for producing many of the bridge girders seen across Washington State, the Northwest, and as far as Alaska and Hawaii. And did you know they also built the Mass Transit Monorail at Walt Disney World? From the cargo-ready Hyundai Terminal at Port of Tacoma to the beloved Fox Island Fishing Pier, you’ll find their lasting contributions to commerce and recreation across Pierce County.

If you’re a sports fan, you have likely sat in one of their stadiums at Safeco Field or a portion of Husky Stadium. They also build detention vaults, floating structures, marine piers, and other massive projects. It’s hard to choose their most noteworthy endeavors – from the I-5 overpass at Grand Mound in Thurston County to the Sheyma Seawall in Sheyma, Alaska, they transport their products everywhere.

For the eco-minded, rest assured that CTC practices sustainability in the way they build. They use quality steel high in recycled content and use regionally available aggregates and cement when possible. They also strive to be as efficient and waste-free as possible, and they have LEED-certification-trained employees on staff.

At the helm of their human resources department is Kaylee Davis. A company veteran who has worked there for more than 10 years, Davis is clearly passionate about the company’s history and achievements. She started her career at Brown & Haley, and after raising a family, the talented Davis returned to school, taking classes in writing and publishing arts, and ultimately graduating from Pacific Lutheran University. She was then recruited by her former mentor at Brown & Haley, Virginia Robinson, to work at CTC. The rest, as they say, is history.

When asked about her tenure, Davis says, “I grew up in a family-owned business, married into a family-owned business, went to work in a family-owned business. I don’t think I could be successful in a large corporation where everyone is a number. I pride myself on knowing everyone’s name. People who work here are all-important to CTC because they provide the backbone for the products we provide. People who work here are willing to help one another be successful.” With more than 200 employees today, the company still stands by its Founders’ Principles.

What impresses her most, after all these years? “The enormity of the products built here are built by hand, usually in a 24-hour cycle. That is an incredible task!”

Concrete Technology is always looking to recruit new talent. Says Davis, “Concrete Tech’s commitment to its employees is what makes me most proud.” Like her own story, Concrete Tech gives the opportunity for a long-term career growth with a full benefits package, on-the-job mentorship and training, and a family company culture that includes special events like barbeques and a fishing derby.

Says Davis, “CTC is culturally diverse. We have people from all over the world! There are about seven different languages spoken here. Yet the work gets done every day—and we come back and do it again.”

If you or someone you know is interested in working at Concrete Technology Corporation, visit their Careers page. You can also follow them on Facebook.